Description

Table of Contents

Introduction: Stop Guessing, Start Simulating

The Thermal Simulation Service we provide eliminates the risks associated with high-power electronic design. Engineers often face a critical decision: stick with traditional Aluminum Nitride (AlN) or upgrade to CVD Diamond. Making the wrong choice can lead to device failure or unnecessary costs. Our Thermal Simulation Service offers a physics-based, accurate prediction of how 6ccvd Diamond Heat Spreaders will perform in your specific device architecture.

Leveraging our in-house team of scientist, we model your exact geometry, power loads, and boundary conditions. This Thermal Simulation Service is essential for teams working with VCSELs, Laser Diodes, and GaN HEMTs who need empirical data to justify the transition to diamond materials.

The 6ccvd Guarantee: If you proceed to order PCD Diamond Heat Spreaders or wafers based on the simulation results, we credit part of the simulation cost back to your hardware order.

Case Study: VCSEL Array (AlN vs. Diamond)

To demonstrate the power of our Thermal Simulation Service, we performed a comparative analysis on a high-power VCSEL diode array. The goal was to determine if replacing the AlN submount with CVD Diamond would significantly lower the junction temperature.

Simulation Setup

- Device: High-Power VCSEL Diode.

- Heat Load: Swept from 10 W to 50 W.

- Comparison: Aluminum Nitride (AlN) vs. CVD Diamond (1400 W/mK).

- Metallization: Standard Ti/Pt/Au included in thermal resistance calculations.

- Boundary Condition: Copper base plate bottom surface maintained at 25°C (simulating active cooling).

Results: 47% Reduction in Temperature Rise

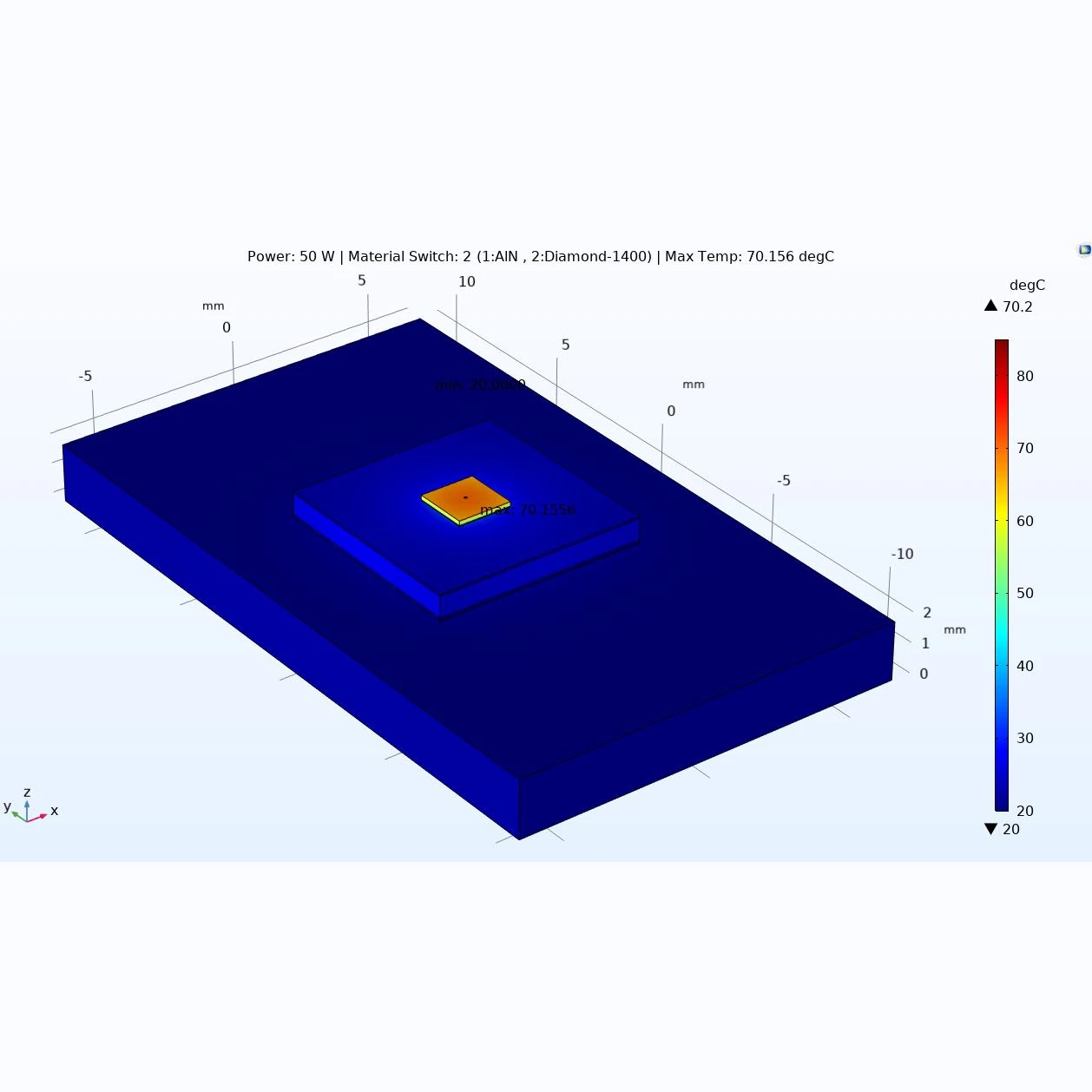

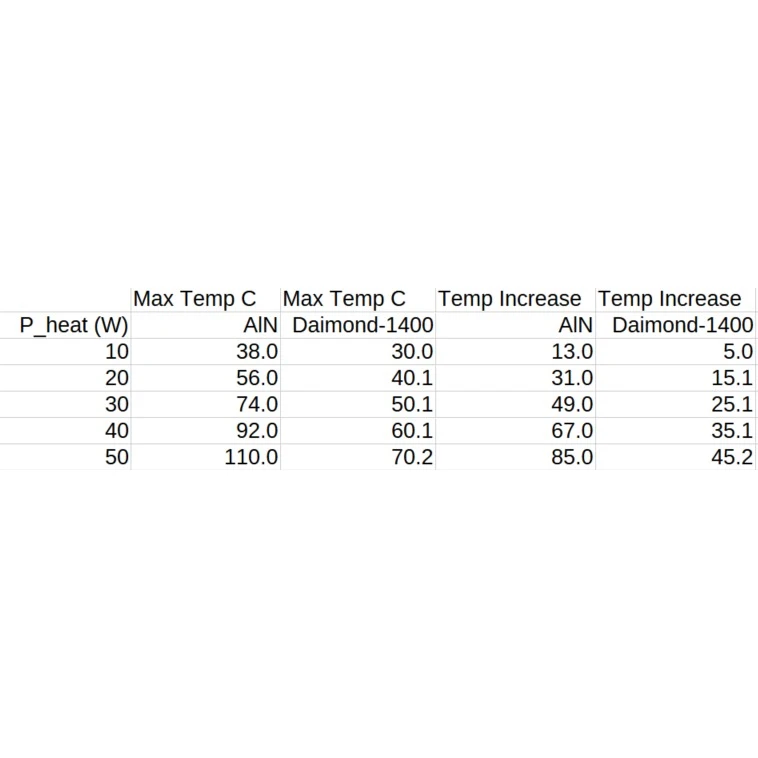

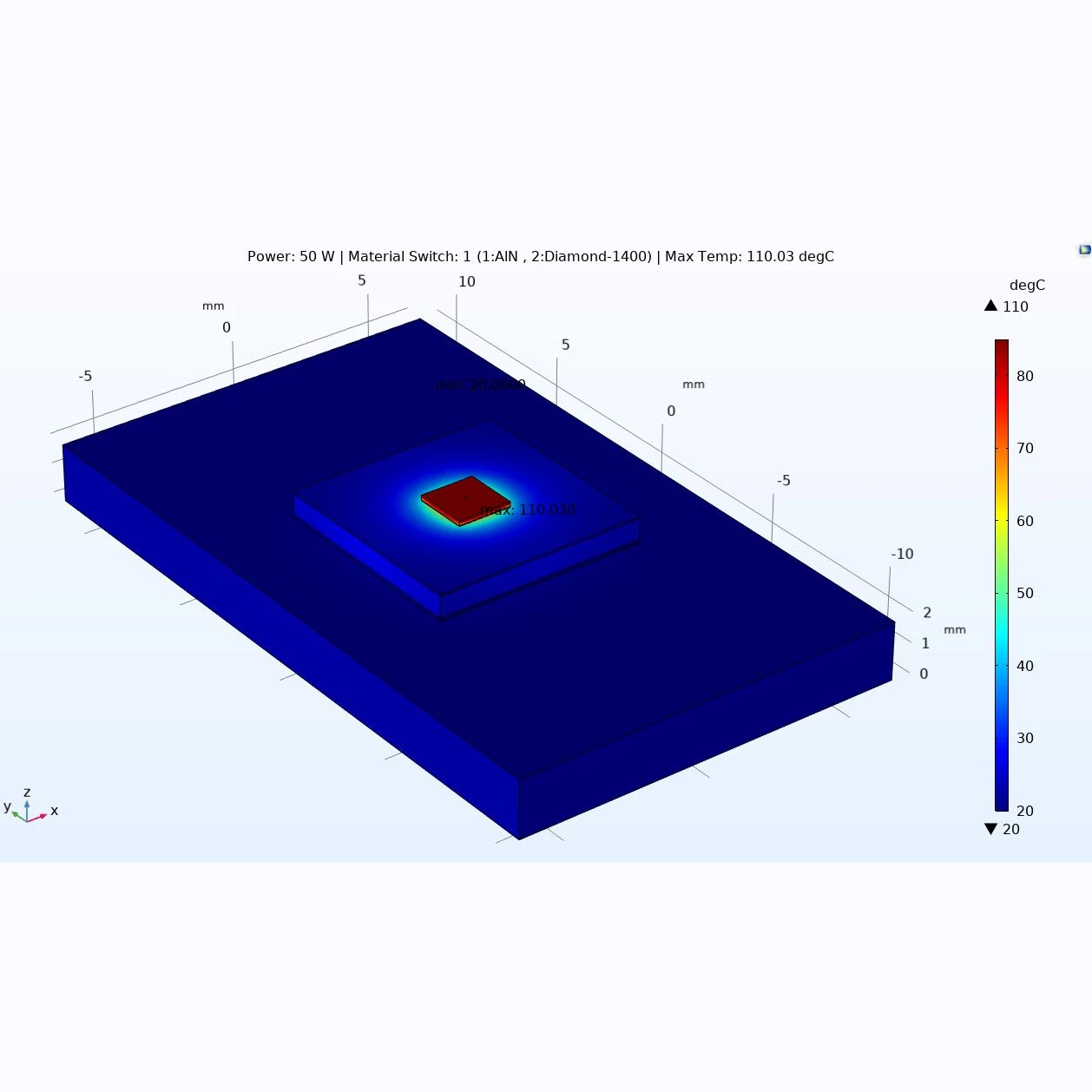

The data below, generated by our Thermal Simulation Service, highlights a massive performance gap. At a 50W load, the AlN submount allowed the device to reach a critical 110°C. In contrast, the Diamond submount kept the device at a stable 70.2°C.

| Power (W) | Max Temp (AlN) | Max Temp (Diamond 1400) | Temp Reduction (°C) |

|---|---|---|---|

| 10 | 38.0°C | 30.0°C | -8.0°C |

| 30 | 74.0°C | 50.1°C | -23.9°C |

| 50 | 110.0°C | 70.2°C | -39.8°C |

This represents a temperature rise reduction of approximately 47% (from a delta of 85°C to 45.2°C). For laser diodes, this reduction can extend device lifetime by orders of magnitude.

Our Methodology & Accuracy

Accuracy is the cornerstone of our Thermal Simulation Service. We do not simply apply a generic thermal conductivity value to a block. We build a multi-physics model that accounts for real-world constraints.

Crucially, we define boundary conditions that match your lab environment. In the VCSEL case above, the simulation did not assume the entire copper block was 25°C. Instead, we applied a fixed temperature boundary condition only to the bottom surface of the copper base. This accurately simulates a real-world scenario where the device is mounted on a water-cooled plate or thermoelectric cooler (TEC), allowing for realistic thermal spreading gradients through the copper thickness.

Technical Specifications

Below are the standard parameters covered by our Thermal Simulation Service. Custom requirements can be discussed via our contact page.

| Material Library | CVD Diamond (1000-2200 W/mK), AlN, BeO, Cu, SiC, GaN, GaAs |

| Simulation Types | Steady-State (Equilibrium) and Transient (Time-dependent heating) |

| Deliverables | PDF Report, 3D Thermal Maps, CSV Temperature Data, Recommendations |

| Typical Turnaround | 5 – 7 Business Days |

Scientific Resources

To further understand the physics behind our Thermal Simulation Service, we recommend reviewing these peer-reviewed studies on diamond thermal management:

- Study on the Preparation of Diamond Film Substrates on AlN (MDPI) – Validates the thermal interface benefits.

- Thermal management strategies for high power lasers (IEEE Xplore) – Discusses the criticality of submount selection.

- Diamond/aluminum nitride composites for efficient thermal management (ScienceDirect).

- Thermal Comparison of Polycrystalline Diamond and AlN (ResearchGate).

Frequently Asked Questions

Q: What data do I need to provide for the Thermal Simulation Service?

A: We require the chip dimensions (length, width, thickness), the heat source power (Watts) or power density, and details on your current submount stack (materials and dimensions).

Q: Can you simulate metallization layers?

A: Yes. As part of our Customization Services, we can account for the thermal resistance of Ti/Pt/Au, Silver, or Copper layers in the model to ensure high fidelity.

Q: Is the cost refundable?

A: The service fee itself is for the engineering time and is non-refundable. However, we offer a “Credit Back” program where the fee is applied as a discount if you subsequently order Single Crystal Diamond or PCD products from us.

Q: How do you handle confidentiality?

A: We regularly work under NDA with our clients. Your proprietary device architecture is kept strictly confidential and is used solely for the purpose of the Thermal Simulation Service.

Reviews

There are no reviews yet.