Description

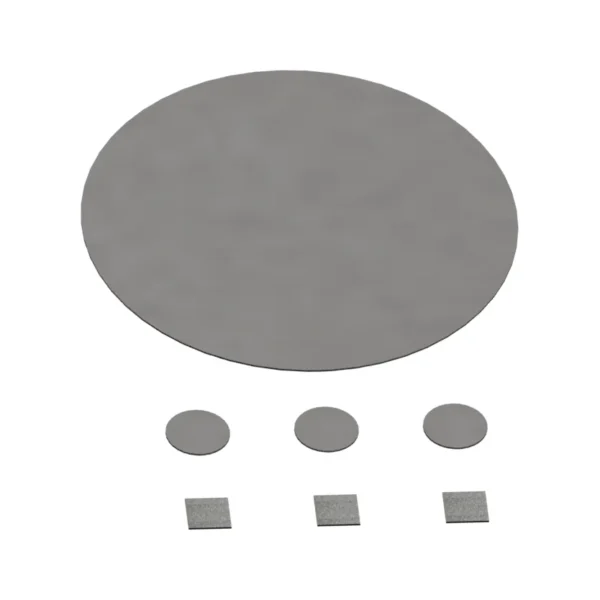

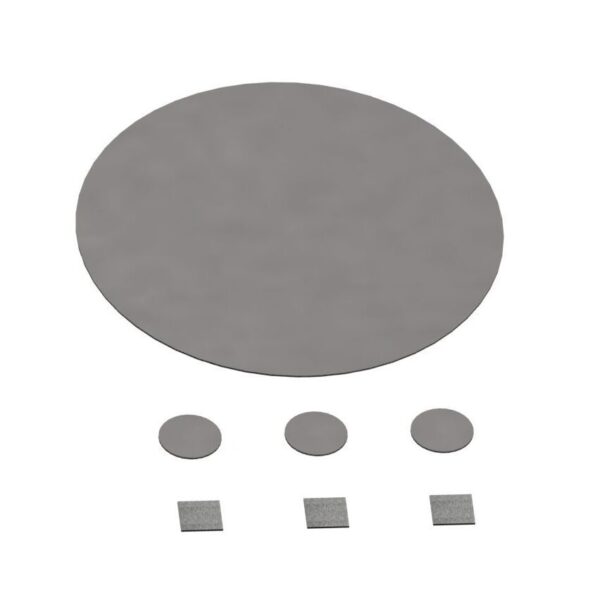

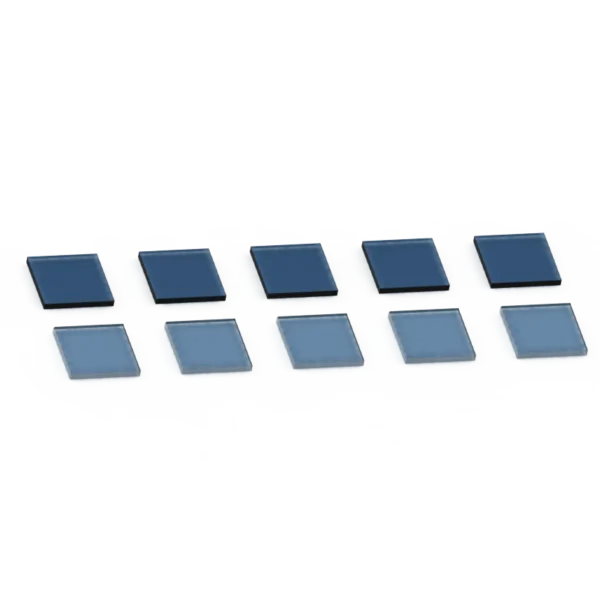

Boron Doped Diamond on Titanium (BDD) Electrode

You know the struggle. You spend weeks setting up an electrochemical experiment or a pilot wastewater treatment plant, only to have your electrodes fail halfway through. It’s frustrating, expensive, and frankly, a waste of your time. If you are dealing with aggressive electrolytes or high current densities, standard metal anodes just don’t cut it.

That is where our Boron Doped Diamond on Titanium (BDD) electrodes come into play. We combine the extreme electrochemical stability of diamond with the mechanical toughness of Grade 5 Titanium (Ti-6Al-4V). This isn’t just another coating; it is a robust solution for when you need to generate hydroxyl radicals efficiently without your substrate falling apart.

Table of Contents

What Makes BDD on Titanium Different?

We grow these electrodes using Microwave Plasma Chemical Vapor Deposition (MPCVD). Unlike standard platinum or dimensionally stable anodes (DSAs), our Boron Doped Diamond on Titanium surface offers an extremely wide potential window. This means you can drive reactions that are impossible with other materials.

The secret lies in the adhesion. Growing diamond on metal is tricky because of thermal expansion mismatches. We solve this by using a specialized SLA pre-treatment on the Ti-6Al-4V substrate before deposition. This ensures the diamond layer sticks through harsh electrolysis cycles.

If you need even higher thermal stability for extreme heat applications, you might want to check our BDD on Niobium electrodes, but for most aqueous applications, Titanium is the industry workhorse.

Real-World Applications

Our clients typically use these electrodes for jobs where failure isn’t an option. Here is where they shine:

- Wastewater Treatment (AOPs): Destroying “forever chemicals” like PFAS and pharmaceutical residues. BDD generates hydroxyl radicals (OH•) that mineralize organic pollutants.

- Electrosynthesis: Creating persulfates or ozone directly in the solution.

- Biosensors: The low background current of diamond makes it perfect for detecting trace biological markers.

- Electroplating: acting as an inert anode that doesn’t contaminate the bath.

For research labs needing pure diamond without the metal substrate, our Single Crystal CVD Diamond Plates might be a better fit for optical or thermal studies.

Technical Specifications

We keep our specs transparent so you know exactly what you are buying. If you don’t see the size you need, just ask.

| Feature | Specification Details |

|---|---|

| Substrate Material | Titanium Alloy Ti-6Al-4V (Grade 5) |

| Diamond Type | Polycrystalline Boron-Doped Diamond (PCD) |

| Standard Dimensions | 1 mm to 100 mm (Customizable) |

| Diamond Thickness | 0.1 µm to 500 µm |

| Doping Level | Heavily Doped (Metallic Conductivity) ~1E20 atoms/cm³ |

| Surface Finish | As-grown (Roughness scales with thickness) |

Why Ti-6Al-4V Substrates?

You might ask, “Why not use Silicon or Niobium?” Good question. While we offer those, Titanium (Grade 5) is the sweet spot for industrial scalability.

Strength: Ti-6Al-4V is mechanically stronger than pure Titanium or Silicon wafers. It handles the rough-and-tumble of industrial flow cells easily.

Cost: It is significantly more affordable than Niobium, making it viable for large-scale wastewater treatment plants.

Machinability: We can easily machine Titanium into complex shapes before coating, unlike brittle Silicon.

Need a weird shape or a specific hole pattern? We can do that. Check out our Customization Services page to see how we handle bespoke requests.

External Scientific Resources

For detailed technical data and peer-reviewed studies on the performance of Boron Doped Diamond electrodes, please refer to the following academic resources:

- ACS Accounts of Chemical Research: Boron-Doped Diamond Electrodes: Fundamentals for Electrochemical Applications

- Frontiers in Materials: In-house vs. Commercial Boron-Doped Diamond Electrodes for Electrochemical Degradation of Water Pollutants

- Journal of Environmental Management: Electrochemical degradation of per- and poly-fluoroalkyl substances (PFAS) using BDD electrodes

- MDPI Environments: Electrochemical Advanced Oxidation Processes Using Diamond Technology: A Critical Review

- Journal of Alloys and Compounds: Relationship between substrate type and BDD electrode structure, performance and antibiotic tetracycline mineralization

- ACS Measurement Science Au: Quantitative Measurement Technique for Anodic Corrosion of BDD Advanced Oxidation Electrodes

- Bioelectrochemistry: Comparison of electrochemical performance of various boron-doped diamond electrodes

- Journal of The Electrochemical Society: Electrochemical Ozone Generation Using Compacted High Pressure High Temperature Synthesized Boron Doped Diamond Microparticle Electrodes

- Carbon: Assessment of acid and thermal oxidation treatments for removing sp2 bonded carbon from the surface of boron doped diamond

- ACS Sensors: Investigation of sp2-Carbon Pattern Geometry in Boron-Doped Diamond Electrodes

- Diva Portal: Electrochemical remediation of PFAS by Boron-Doped Diamond electrodes: A review

Frequently Asked Questions

How durable is the Boron Doped Diamond on Titanium coating?

It is exceptionally durable. The diamond is chemically inert. The main failure mode for BDD electrodes is usually delamination of the substrate, not the diamond itself. That is why we use Grade 5 Titanium and specialized surface prep to maximize adhesion longevity.

Can I use this for drinking water disinfection?

Absolutely. BDD is famous for generating ozone and mixed oxidants directly from the water without adding chemicals. It is a clean way to disinfect.

Do you offer custom dimensions?

Yes, we do. While our standard plates go up to 100 mm, we can machine the Titanium substrate to your specific drawing before coating. Just shoot us a message for a quote.

What is the lead time?

Standard sizes usually ship within 1 month. Custom shapes might take a bit longer depending on the machining requirements.

Reviews

There are no reviews yet.