Description

Biomedical Diamond Coating on Titanium: The Future of Implant Technology

We understand the critical challenges engineers and medical researchers face when developing next-generation implants. You need a surface that resists wear, fights infection, and bonds with bone, all without compromising the structural integrity of the titanium substrate. Our Biomedical Diamond Coating on Titanium provides the robust solution your project demands. By applying a precise layer of CVD diamond to customer-supplied Titanium components, we transform standard medical-grade alloys into bioactive, high-performance interfaces.

Whether you are designing orthopedic joint replacements or delicate neural sensors, our Biomedical Diamond Coating on Titanium service delivers a surface that is chemically inert yet biologically active. We use advanced Microwave Plasma Chemical Vapor Deposition (MPCVD) to grow diamond directly onto complex 3D shapes, ensuring conformal coverage that traditional line-of-sight coatings cannot match.

Table of Contents

The Science: Why Diamond on Titanium?

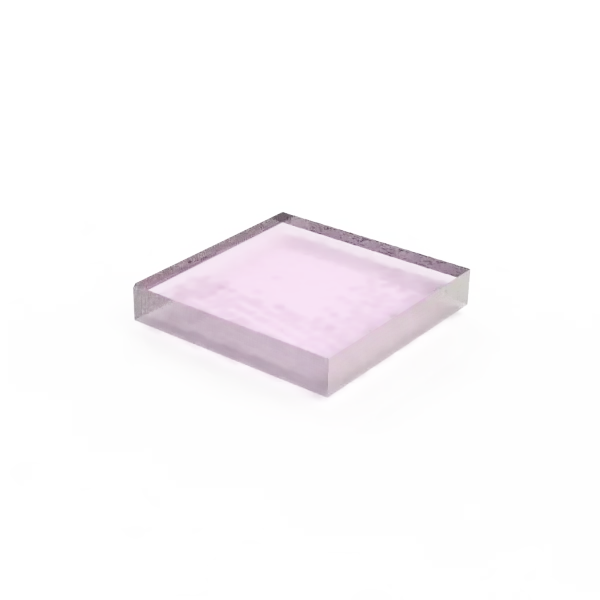

Titanium (Ti-6Al-4V) is the industry standard for strength, but it lacks the surface hardness and biological affinity required for long-term success in the human body. Our Biomedical Diamond Coating on Titanium bridges this gap. We grow Nanocrystalline Diamond (NCD) or Boron-Doped Diamond (BDD) directly on the metal, creating a chemical bond that prevents delamination.

Recent studies confirm that Biomedical Diamond Coating on Titanium significantly enhances osseointegration. The nano-topography of our diamond coating mimics the structure of natural bone, encouraging osteoblasts to attach and proliferate more faster than they do on bare titanium. Furthermore, the hydrophobic nature of undoped diamond—or the tunable wettability of our treated surfaces—drastically reduces bacterial adhesion, lowering the risk of post-surgical infection.

Real-World Applications

Our clients utilize Biomedical Diamond Coating on Titanium across a variety of demanding medical fields. Here is where we see the most impact:

- Orthopedic Implants: Hip and knee replacements benefit from the extreme hardness (approx. 60 GPa) of the coating, which virtually eliminates the release of toxic metal ions due to wear.

- Dental Screws: The superior osseointegration of Biomedical Diamond Coating on Titanium ensures better mechanical stability in the jawbone.

- Bone Tissue Scaffolds: We coat porous 3D-printed titanium scaffolds, promoting bone ingrowth deep within the structure.

- Neural Electrodes: Our Boron-Doped Diamond (BDD) options provide a wide electrochemical window and low background current, ideal for long-term neural recording without signal degradation.

- Cardiovascular Stents: The hemocompatibility of diamond reduces the risk of thrombosis compared to bare metal.

- Surgical Tools: Diamond-coated scalpels and drills maintain their edge longer and reduce friction during procedures.

If you are exploring other substrate options for electrochemical applications, you might also consider our Boron-Doped Diamond (BDD) Electrode on Silicon or our specialized BDD on Niobium products.

Technical Specifications

We pride ourselves on transparency. Below are the standard capabilities for our Biomedical Diamond Coating on Titanium service. Note that we can customize these parameters for specific research or commercial needs.

| Feature | Specification |

|---|---|

| Substrate Material | Customer-supplied Titanium (Ti-6Al-4V Grade 5 preferred) |

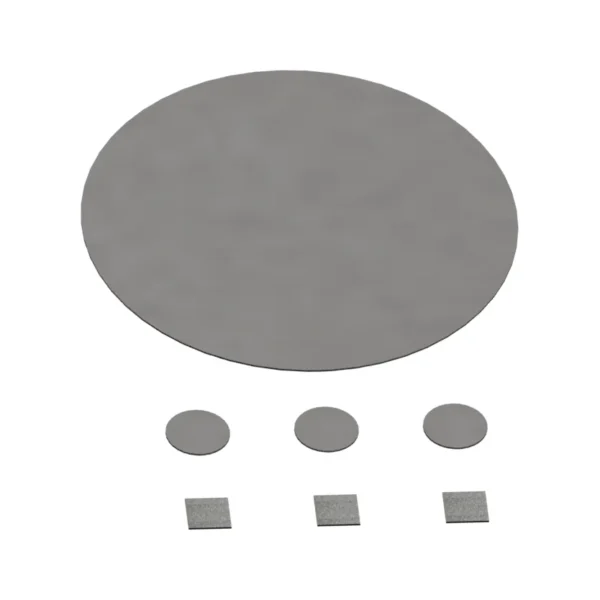

| Diamond Type | Nanocrystalline (NCD) or Boron-Doped (BDD) |

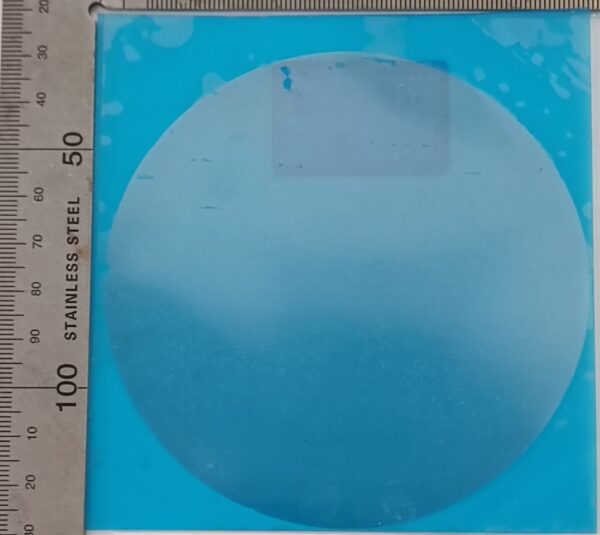

| Deposition Area (Max) | Up to 125 mm diameter (Custom 3D shapes allowed) |

| Coating Thickness | 0.1 µm to 500 µm (Tunable) |

| Surface Roughness | As-grown or Polished (Nanoscale roughness available) |

| Hardness | ~60 GPa to 100 GPa (Depending on diamond phase) |

| Bioactivity | Tunable (Hydrophilic or Hydrophobic) |

| Lead Time | 1 Month (Standard) |

For projects requiring high thermal conductivity alongside bio-compatibility, check our PCD Diamond Heat Spreader capabilities.

External Scientific Resources

We base our processes on rigorous scientific data. Here are key papers supporting the efficacy of Biomedical Diamond Coating on Titanium:

- Smart Materials in Manufacturing (2026): Could diamond coatings provide a better osseo-interface for 3D-printed titanium implants? (Shows improved push-out force from 155N to 190N).

- Frontiers in Neuroscience (2016): Boron-Doped Nanocrystalline Diamond Electrodes for Neural Interfaces. (Evidence of milder inflammatory reaction compared to TiN).

- MDPI Coatings (2020): Osteoconductive and Osteoinductive Surface Modifications of Biomaterials.

- Diamond and Related Materials (2020): Deposition of highly adhesive nanocrystalline diamond films on Ti substrates.

- Scientific Reports (2020): Microscale diamond protection for sensors.

- Journal of Composites Science (2021): Nanocomposites for Enhanced Osseointegration of Dental and Orthopedic Implants.

- Surface and Coatings Technology (2021): Highly uniform polycrystalline diamond coatings of three-dimensional structures.

- Biointerphases (2020): Metallic additive manufacturing for bone-interfacing implants.

- Medical Devices & Sensors (2020): Diamond in medical devices and sensors: An overview of diamond surfaces.

Frequently Asked Questions

How do I request a quote for Biomedical Diamond Coating on Titanium?

Since this is a custom service involving customer-supplied parts, please use our contact form. Include your component dimensions, quantity, and desired coating thickness so we can provide an accurate estimate.

What is the adhesion quality of the diamond layer?

Adhesion is our top priority. We use specialized SLA pre-treatment and interlayer technologies to ensure the Biomedical Diamond Coating on Titanium remains chemically bonded to the substrate, even under high mechanical loads.

Can you coat complex 3D shapes?

Yes. Our MPCVD technology allows for conformal coating on complex geometries, including porous scaffolds and screw threads, ensuring the entire surface benefits from the Biomedical Diamond Coating on Titanium.

What are your shipping terms?

Standard shipping is DDU (Delivered Duty Unpaid). If you require DDP (Delivered Duty Paid), please provide your recipient details and Tax ID when requesting a quote.

Reviews

There are no reviews yet.